Membrane and depth filtration differ in principles and applications. Membrane suits precise separation in pharmaceuticals, while depth filtration excels in capturing larger particles for water treatment and food production. The choice depends on specific needs for particle separation and filtration efficiency.

This article aims to delve into the realm of filtration techniques, focusing specifically on the dynamic interplay between membrane and depth filtration. We’ll explore the fundamental differences, intricate mechanisms, and practical applications of these two pivotal methods.

Understanding the basics of filtration techniques

Filtration techniques are essential processes used in various industries to separate solids from liquids or gases. These methods play a crucial role in purifying substances and ensuring the quality of final products.

Types of Filtration Techniques

Mechanical Filtration:

Mechanical filtration involves the use of physical barriers to trap particles. Common examples include sieves, screens, and membranes. This method is effective for removing larger particles from liquids or gases.

Depth Filtration:

Depth filtration utilizes a porous medium to retain particles throughout its depth. It is particularly effective for capturing smaller particles that may pass through mechanical filters. Examples of depth filtration media include sand, activated carbon, and diatomaceous earth.

Surface Filtration:

Surface filtration relies on a membrane or barrier to capture particles on its surface. This method is highly efficient for removing contaminants and microorganisms. It is widely used in pharmaceutical, biotechnology, and water treatment applications.

Applications of Filtration Techniques

Water Treatment:

Filtration is a critical step in water treatment processes. It helps remove impurities, sediment, and microorganisms, ensuring the delivery of clean and safe drinking water.

Pharmaceutical Industry:

In the pharmaceutical sector, filtration techniques are employed to purify drugs, separate solids from liquid solutions, and maintain the integrity of sensitive biological materials.

Food and Beverage Production:

Filtration is integral in the food and beverage industry to clarify liquids, remove impurities, and enhance product quality. It is commonly used in processes such as beer brewing, winemaking, and fruit juice production.

Significance of Filtration Techniques

Quality Assurance:

Filtration ensures the removal of contaminants, contributing to the overall quality and safety of products. This is crucial in industries such as healthcare, where the purity of substances is paramount.

Environmental Protection:

Filtration plays a role in environmental protection by preventing the release of pollutants into air or water sources. It aids in maintaining ecological balance and sustaining ecosystems.

Process Efficiency:

Employing appropriate filtration techniques enhances process efficiency by preventing equipment damage and optimizing production processes. It reduces downtime and increases the longevity of industrial systems.

From mechanical to surface filtration, these methods are indispensable for achieving purity, safety, and efficiency in various processes. As technology advances, innovative filtration techniques continue to emerge, further expanding the capabilities of this fundamental process.

What Is Membrane Filtration?

Membrane filtration is a physical separation method characterized by its ability to separate molecules of different sizes and properties. The driving force is the pressure difference on either side of a special membrane. Membrane technology can reduce overall production costs while improving product quality.

Types of membrane filtration

There are four common types of membrane filtration, which are defined based on their ability to separate the size of substances in the feed liquid. The four types are reverse osmosis, nanofiltration, ultrafiltration and microfiltration, arranged in order from small to large pore size. Our flat sheet membranes and spiral membranes cover these membrane filtration types.

1. Reverse Osmosis (RO)

Utilizes the tightest possible membranes for liquid separation.

In principle, only water can pass through the membrane, and all other substances (bacteria, spores, fats, proteins, colloids, salts, sugars, minerals, etc.) cannot pass.

2.Nanofiltration (NF)

Small ions (such as minerals) are allowed to pass while larger ions and most organic components (such as bacteria, spores, fats, proteins, colloids, and sugars) are excluded.

3. Ultrafiltration (UF)

Use membranes with larger pore sizes and relatively low pressures. Salts, sugars, organic acids, and smaller peptides are allowed to pass through, while proteins, fats, and polysaccharides are not.

Read about our UF Flat Membranes and UF Spiral Membranes

4. Microfiltration (MF)

In microfiltration, suspended solids, bacteria and fat particles are usually the only substances not allowed to pass through.

Read about our MF flat sheet membranes and MF spiral membranes.

Advantages of membrane filtration

Membrane filtration offers many significant advantages in industrial-scale applications, especially where reliability, consistency and operating costs are critical.

1. Reduce overall production costs

Membrane filtration systems tend to be less expensive than many other alternative technologies. Installation costs are lower and energy costs are lower as well. Membrane filtration involves fewer processing steps, allowing for a higher degree of purity and higher overall yields. Additionally, since membrane filtration does not produce filter cake, there is no cost of treatment and disposal of these residues.

2. High flexibility

Membrane filtration can be used with feed products of varying viscosities, including high-viscosity products that are often difficult to handle. A wide range of different membrane filtration products ensures the best solution for every specific application. This also eliminates unnecessary energy costs.

3. High-end product quality

Membrane filtration is a clean technology. The separation process is based solely on molecular size, without the use of additives. This results in a high-quality final product that more easily meets stringent requirements from consumers and public agencies.

Exploring the strengths and weaknesses of depth filtration

Depth filtration is a process achieved by directing fluid through a mass filter media, creating a convoluted path with numerous entrapments to halt contaminants.

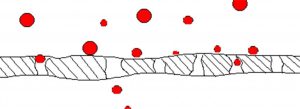

Typically constructed with layered fibrous material, depth filters have an outer layer designed to capture larger particles, while the inner, more densely packed layer is positioned to capture finer particles. This mechanical retention filtration ensures that the media can retain a significant volume of solids before becoming clogged, maximizing the filter’s efficiency.

Surface Filtration vs Depth Filtration

In essence, the primary distinction between these two filters lies in how they retain particles. Surface filters retain particles solely on the surface of the media, while depth filters retain particles throughout the media.

Surface filtration defines the size of particles removed by the pore size of the media. These filters can develop a “filter cake,” increasing efficiency by 30-40%.

On the other hand, depth filters often begin with a 99% efficiency rating and do not rely on a “cake layer” to enhance holding capacity. Using a sieving mechanism, depth filters can filter out both large and small particles. They not only retain a greater volume of particles than surface filters but can also filter a wider range of particle sizes, making them well-suited for complex filtration applications.

Different Types of Depth Filter Cartridges

String Wound Filter Cartridges

Wound cartridges are crafted with layers of cotton or polypropylene string spun around a central core, forming a depth filter with higher efficiency, lower pressure drop, and greater solids holding capacity compared to standard elements at competitive prices.

Graded Density Filter Bags

Filter bags can retain a large number of contaminants without clogging and produce excellent results when used as a pre-filter for membrane filtration. Available in either all polyester or all polypropylene construction.

The key differences between membrane and depth filters, and their application

Filtration is a critical process in various industries, ensuring the removal of impurities and contaminants from fluids and gases. This article explores the key differences between membrane and depth filters, shedding light on their applications.

Membrane Filters vs. Depth Filters

Filtration Mechanism

Membrane Filters: These feature a thin, semi-permeable membrane with specific-sized pores, allowing the passage of particles smaller than the pore size while blocking larger particles.

Depth Filters: Composed of porous materials like fibrous media, depth filters trap particles within their structure as fluid flows through, effective for contaminants of various sizes.

Precision of Filtration

Membrane Filters: Known for precise separation, crucial in applications such as pharmaceutical manufacturing, biotechnology, and electronics.

Depth Filters: Effective for a wide range of particle sizes, making them suitable for industries like pharmaceuticals, food and beverage, and water treatment.

Applications

Membrane Filters: Widely used for applications requiring fine filtration, such as in pharmaceuticals for product sterility and electronics for microchip manufacturing.

Depth Filters: Commonly employed in industries like water treatment, food and beverage, and pharmaceuticals for clarification, purification, and sterilization processes.

Selecting the right filter is crucial for optimizing efficiency and meeting specific requirements. Membrane filters excel in precision applications, ensuring the removal of minute particles, while depth filters offer versatility in handling contaminants of various sizes.

Businesses seeking optimal filtration solutions should carefully consider their specific needs, industry standards, and the nature of contaminants to make informed choices between membrane and depth filters. This strategic decision plays a vital role in achieving product quality, equipment longevity, and overall operational efficiency.

Key considerations when choosing between membrane and depth filtration

In routine sample filtration, the often-overlooked factor of filter material compatibility can significantly impact outcomes. Researchers may select filters based on convenience, but understanding the properties of different filter membrane materials is crucial for optimal filtration efficiency and preventing unexpected issues.

Hydrophilic vs. Hydrophobic Membranes

Hydrophobic membranes, like PTFE, resist aqueous samples, leading to back pressure and potential membrane rupture. Pre-wetting with alcohol can alleviate this, making hydrophobic materials suitable for organic samples. However, prolonged exposure may lead to swelling and reduced performance.

Membrane Compatibility with Solvents

Organic solvents are well-handled by hydrophobic materials, but some can be absorbed, affecting the membrane’s pore size and performance. Solvents may also induce chemical reactions, releasing extractables into the filtrate. Highly inert materials like PTFE are preferable for extreme pH samples.

Depth Filtration for High-Particulate Samples

Surface filters (membranes) trap particles on the top surface, making them suitable for low-particulate samples but prone to clogging. Depth filters, like asymmetric PES, excel in high-particulate applications by trapping particles within their fiber matrix. Their layered structures minimize clogging issues.

Protein Binding and Extractables

Hydrophilic materials like nylon exhibit high protein binding, making them unsuitable for protein recovery and analysis. Extractables, originating from membrane-sample incompatibility, can impact sensitive downstream analytical techniques. Materials like PTFE, PVDF, and RC show compatibility with various solvents, remaining low in extractables.

pH Considerations

pH is a critical factor in membrane compatibility. Highly inert membranes, such as PTFE, are recommended for extreme pH samples, as strongly acidic or alkaline solvents can impact membrane integrity over time.

A proactive approach to membrane and depth filtration selection, considering sample compatibility, pH, and particle content, can minimize troubleshooting efforts and enhance overall filtration efficiency. Choosing the right filtration strategy ensures reliable results and optimal performance in diverse industrial applications.

Conclusion

The battle between membrane filtration technology and depth filtration technology highlights the critical role of filtration in industrial processes.

An exploration of their fundamentals, strengths, and applications reveals the nuanced landscape where each approach excels. To achieve the best results, companies must carefully consider their specific needs, industry standards and the nature of the contaminant.

Whether it’s the precision of a membrane filter or the versatility of a depth filter, the strategic choice between these technologies can significantly impact product quality, equipment longevity and overall operating efficiency.

As the industry evolves, embracing advancements in filtration technology is critical to staying ahead of the curve on the ongoing journey to industrial excellence. Contact us today to help you choose the right and efficient filtration method.

Let’s help you find solution suites your needs.

Explore more how we can solve your toughest problems in critical filtration.