In various industries, filtration is a critical process that ensures the purity and safety of products, protecting both consumers and equipment. From pharmaceuticals to food and beverage production, the need for critical process filtration is paramount.

There are many types of filters designed to meet different needs, but capsule filters are particularly noteworthy for their efficiency and convenience. But what exactly is a capsule filter, and why is it so significant?

Defining Capsule Filters

A capsule filter is a self-contained, ready-to-use filtration unit designed for a wide range of applications across various industries. Unlike traditional filters, which often require separate housings and complex assembly, capsule filters come pre-assembled, offering significant advantages in terms of convenience and contamination control. This unique design makes capsule filters an ideal choice for critical processes where maintaining sterility and purity is critical.

Structure and Components

Capsule filters consist of a compact housing that encases the filter media. The housing is typically made from robust, chemically resistant materials such as polypropylene, which ensures durability and compatibility with a variety of fluids. The filter media inside the capsule can vary, tailored to meet specific filtration requirements.

Common materials used for the filter media include:

- Polypropylene (PP) Membrane: Known for its chemical resistance and broad compatibility with different fluids.

- Polyethersulfone (PES) Membrane: Preferred for its high flow rates and low protein binding, making it suitable for biopharmaceutical applications.

- Polyvinylidene Fluoride (PVDF) Membrane: Offers excellent chemical resistance and is often used in critical filtration processes.

- Polytetrafluoroethylene (PTFE) Membrane: Known for its hydrophobic properties, suitable for gas and solvent filtration.

- Nylon Membrane: A versatile material with good mechanical strength and compatibility with many solvents.

Principle of Working of Capsule Filters

Capsule filters operate by guiding fluid through a structured filtration process. The fluid enters through the inlet, filling the filter housing and displacing any air, which is expelled through an exhaust port that is then closed. As the fluid passes through the filter media, a pressure difference drives the fluid through the pores, where larger particles are trapped while smaller particles pass through, effectively separating impurities by size.

After the filtration process is complete, the purified fluid exits through the outlet. Any remaining filtrate can be discharged by opening a valve at the bottom of the filter housing, ensuring that all filtered fluid is collected and any residual contaminants are removed. By leveraging the principles of pressure differential and selective particle retention, capsule filters efficiently separate impurities from the fluid.

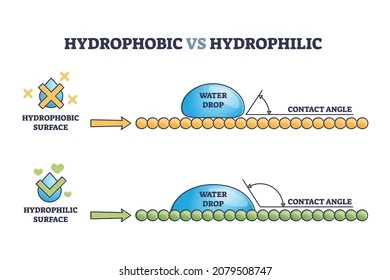

Difference Between Hydrophilic and Hydrophobic Filters

The type of capsule filters used can significantly impact the filtration process. Hydrophilic and hydrophobic filters are two primary types, each suited for different applications.

Hydrophilic filters are designed to be easily wetted by water and can be used with virtually any liquid. They are ideal for aqueous solutions due to their compatibility with water-based fluids. However, once wetted, these filters do not allow the free passage of gases until the applied pressure exceeds the bubble point, forcing the liquid out of the membrane’s pores.

In contrast, hydrophobic filters do not wet with water but are readily wetted by low surface tension liquids, such as organic solvents like alcohols. When a hydrophobic filter is wetted by these solvents, it can also allow aqueous solutions to pass through. These filters are particularly well-suited for applications involving gas filtration, low surface tension solvents, and venting.

In some cases, hydrophobic filters may be used for aqueous solutions depending on compatibility requirements. However, water or aqueous solutions can only pass through a hydrophobic filter once the water breakthrough pressure is achieved.

Benefits of Capsule Filters

Capsule filters offer several significant advantages that make them a preferred choice in various filtration applications:

Convenience and Ease of Use

Capsule filters are pre-assembled and ready for immediate use, which simplifies the filtration process. This eliminates the need for additional housing or complex setup, reducing installation time and minimizing contamination risks associated with manual assembly.

Compact Design

Their space-efficient, self-contained design makes capsule filters ideal for applications where space is limited. The compact nature allows for easy integration into existing systems without requiring extensive modifications.

Reduced Contamination Risk

The sealed construction of capsule filters minimizes the risk of contamination. Being pre-assembled and sealed, these filters help maintain the purity of the filtered fluid and reduce the likelihood of introducing contaminants during installation.

High Performance and Versatility

Capsule filters are available in a range of pore sizes and membrane types, which allows for precise filtration tailored to specific needs. They deliver consistent and reliable performance across various industries, including pharmaceuticals, food and beverage, biotechnology, and industrial processes.

Cost-Effectiveness

The disposable nature of capsule filters minimizes maintenance and cleaning costs. They are designed to be easily replaced, which reduces downtime and overall filtration costs, making them a cost-effective choice for many applications.

Applications of Capsule Filters

Capsule filters are highly versatile and used across several industries due to their efficiency and ease of use: