In the beverage industry, ensuring the quality and safety of beverages is paramount, making filtration an essential aspect of production. A proper filtration system helps ensure that water quality meets regulatory standards, thus ensuring product compliance.

Among the various filtration options available, capsule filters stand out as highly efficient filtration devices. One notable advantage is their disposability – after a single use as a filter cartridge, they can be conveniently discarded. This feature makes capsule filters widely favored in the beverage industry.

So, which capsule filter is the best choice for the beverage industry? Let’s explore together.

Why is Filtration Essential in the Beverage Industry?

Filtration is effective in controlling microorganisms in water, such as bacteria, molds and yeast. This prevents these microorganisms from being present in the beverage, which in turn prevents the product from spoiling, deteriorating or posing a health risk to the consumer.

Furthermore, filtration enhances the color, odor, and taste of water, particularly during beverage manufacturing, ensuring consistent quality and flavor in the final product.

Additionally, filtration is essential for safeguarding process equipment by preventing waterborne particles and microorganisms from entering the machinery.

This prolongs equipment lifespan, reduces maintenance costs, maintains efficient equipment operation, and minimizes the risk of breakdowns and production interruptions.

By implementing an effective filtration system, beverage producers can ensure that water quality complies with relevant regulations, thereby upholding product integrity and safety standards.

What Is a Capsule Filter?

| Application Fields | Examples of Filtration |

| Beverage Industry | Domestic drinking water, mineral water, fruit juice, fruit wine, and other beverages |

| Food Industry | Beer, wine, and other alcoholic beverages |

| Other Industries | Compressed air, nitrogen, and other gases |

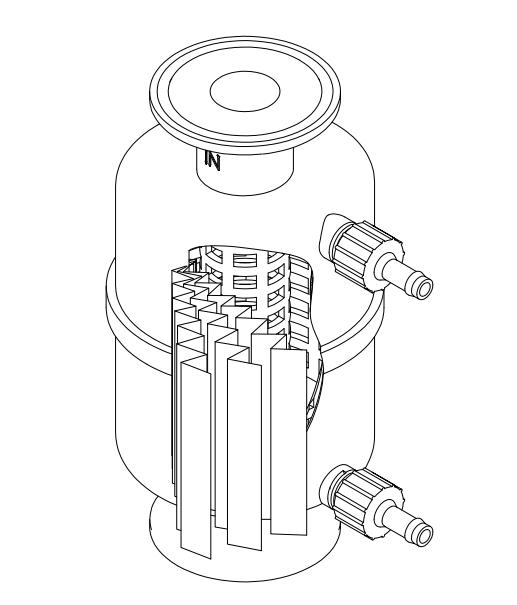

A capsule filter is a one-piece filter with a folded imported membrane, which has a large filtration surface area and is suitable for filtration of larger volume solutions. The exterior of this filter is made of polypropylene, free of adhesives and other chemicals, ensuring no contamination of the sample.

The capsule filter element, also known as a disposable filter element, is strictly speaking a filtration unit and should be categorized as a filter. Due to their small size and filtration area, capsule filters are ideal for small flow rates of liquid and gas filtration.

The Feature of The best choice of capsule filter

- High Filtration Efficiency: Utilizes premium filtration media and precise pore size design to effectively eliminate impurities and microorganisms from the solution, ensuring beverage purity.

- Bio-safety and Non-toxicity: Manufactured in a sterile environment to guarantee bio-safety and non-toxicity, prioritizing consumer health and safety.

- Versatile Applicability: Designed to meet the demands of various beverage production processes, capable of solvent filtration across a wide range of pH values and temperatures, including beverages and fruit juices.

- Diverse Specifications: Offers a range of length and specification options to accommodate different processing capacities and flow rates, optimizing filtration effectiveness.

Discover Advanced Solutions for Beverage Filtration

Sanitek filtration systems are renowned for their efficiency, durability, and faultless performance, ensuring the utmost product quality and microbiological purity.

Tailored specifically for beverage production, Sanitek product systems provide the perfect solution for every stage of the filtration process, from initial production to final filtration.

With Sanitek’s expertise and experience, production and filling processes achieve unparalleled levels of quality and efficiency.

Filtration Solutions For Beer Production

Sanitek offers a wide range of beer filtration equipment designed to meet different needs. These include pre-filters, which can be used as standard filter cartridges, filter modules or filter sheets. Pre-filters provide reliable protection by effectively retaining particles and clarifying the beer.

For the final aseptic filtration step in the beer production process, Sanitek’s capsule filters offer the optimal solution. Designed specifically for beer production, these filters ensure excellent performance and reliability during the aseptic filtration stage.

Filtration Solutions For Wine Production

When looking for the right filtration equipment consumables for your wine production process, you need to consider the aspects of aseptic filtration and minimizing beverage spoilage.

Sanitek filtration and microbiological solutions for wine production are designed to enhance taste, quality, efficiency and safety.

By using Sanitek’s filtration equipment consumables, you can ensure that your wine is adequately filtered and protected during the production process, minimizing the risk of microbial contamination and beverage spoilage.

- Aseptic filters: Sanitek offers aseptic filters designed specifically for wine production, which ensure aseptic conditions at the final filtration stage, thus maintaining the purity and quality of the wine.

- Filter cartridges: Pre-filter cartridges are used to capture suspended particles and impurities, ensuring that the wine is initially filtered before entering the aseptic filter, reducing the burden on the subsequent filtration process.

Filtration Solutions For Juices And Soft Drinks

We offer filtration solutions designed specifically for juice and soft drink production, designed to enhance product taste, quality, efficiency and safety.

Multi-targeted pre-filtration

Our pre-filters can be used as standard capsule filters to retain particles and clarify liquids, as well as provide protection. These prefilters are carefully designed to ensure optimal results during the initial filtration phase of the beverage production process.

Sterile filtration for juices and soft drinks

We offer a wide range of innovative sterilization filtration solutions for efficient purification and sterilization in the beverage industry.

These solutions utilize high quality filtration media and pore size design to ensure high filtration efficiency.

Our manufacturing process is carried out in strict compliance with clean environment standards to ensure that our products are biologically safe and non-toxic.

Product Features

- Utilizes high-quality filter media and well-designed pore size to ensure efficient filtration performance.

- The fabrication process is in accordance with clean environment standards to ensure the bio-safety and non-toxicity of the product.

- Provide a variety of sizes and length options to meet the needs of different processing capacity and flow rate.

- Widely used in the production process of beverages, fruit juices, soft drinks, and beer.

Conclusion

Sanitek Filter offers a comprehensive range of solutions for bioburden control, sterilization, and particle removal, including cartridge, capsule, and laboratory-scale filters.

These cutting-edge filters are ideal for various applications such as bottling, conditioning, raw material hydration, process equipment cleaning, and filling operations, ensuring the water purity required for your production processes.

If you’re considering filtration to enhance efficiency and reduce overall system costs, Sanitek Filter Engineers can assess your current system and provide expert recommendations to mitigate potential risks while meeting your water purification objectives.

Count on our team of professionals to collaborate with you in developing a customized solution tailored to your specific business requirements.

Let’s help you find solution suites your needs.

Explore more how we can solve your toughest problems in critical filtration.